You currently got {{basket.latestItemAddedToBasket.TotalBasketQuantity ? basket.latestItemAddedToBasket.TotalBasketQuantity : basket.latestItemAddedToBasket.Quantity}} item(s) of this product inside your cart.

You currently got {{basket.latestItemAddedToBasket.TotalBasketQuantity ? basket.latestItemAddedToBasket.TotalBasketQuantity : basket.latestItemAddedToBasket.Quantity}} item(s) of this product inside your cart.

In pneumatics, compressed gases are used to set a system in motion, usually air. This air is also referred to as compressed air. The compressed air sets a pneumatic system in motion.

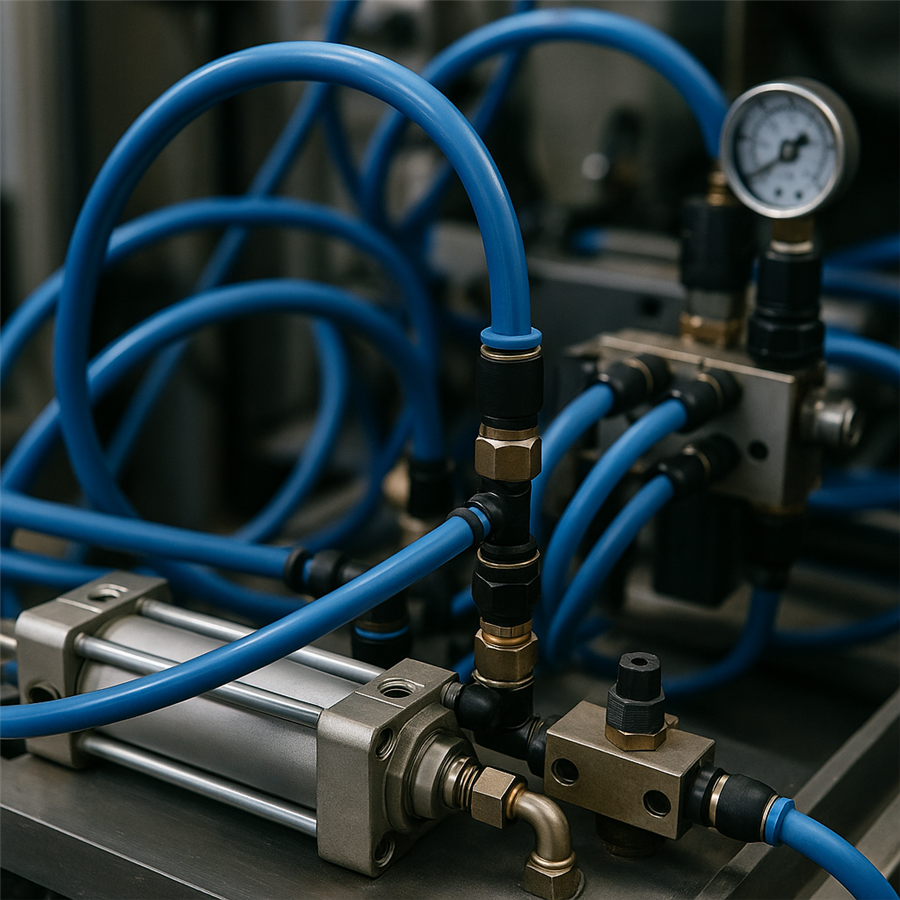

A compressor compresses the air to a desired number of bar. This compressor is connected to a pneumatic hose with a number of valves. These valves determine which hose receives compressed air and which does not. The valves also determine the pressure of the compressed air flowing through the hoses. A valve is therefore a kind of switch in pneumatics. When a valve is open, the compressed air flows through the hoses to, for example, a cylinder. The cylinder is a pneumatic actuator and is set in motion by the pneumatic system. When the cylinder moves, the pneumatic energy is converted into kinetic energy. This ensures that work can be performed.

Pneumatics are used in various machines and devices. For example, the opening and closing of doors in trains and buses is a pneumatic system. You can recognise pneumatics here by the hissing sound you hear when the doors open and close. Pneumatics are also used in tools. This could be for tightening screws or bolts, for example. In addition, pneumatics can be used in machine line systems in the process industry.

Pneumatics as a drive technology has a number of advantages. Pneumatic systems are inexpensive and reliable. Pneumatics also has a number of other advantages, namely: